This article features otherwise unpublished food safety management data held by BRCGS and Safefood 360° which, combined with real-time events, provides an unparalleled view of current and emerging issues and trends in the food safety industry.

The last article reviewed issues and incidents over the last 18 months with a particular focus on food recalls in 2023. Such events are often said to be “inevitable” given the scale and complexity of our global food system but it should be an aspiration of every food safety professional to eliminate these occurrences by deploying preventative measures thereby protecting customers and businesses. Notwithstanding this aspiration, it follows that any business encountering a product recall should conduct a thorough review of the underlying reasons to ensure that measures are introduced to prevent its recurrence. Best practice for this is recognised as being the adoption of Root Cause Analysis (RCA).

Background

RCA is a systematic approach to identifying the fundamental reason for a specific event, be that a product recall or non-conformance. RCA is one of the tools used in Six Sigma, a set of methodologies designed to improve business processes, increase quality and efficiency and reduce defects, errors and variation. There are many texts on RCA and the UK Food Standards Agency (FSA) has published a great introductory 8 minute video to basic root cause analysis using the Five Whys method for those wishing to ease their way into the topic. RCA is not just a technique used in the food industry but something that is universally applied across many sectors and industries to support continuous development. The IT company IBM provides an excellent overview of RCA and the different methodologies that can be applied. A detailed report on conducting a food safety root cause analysis has been published by the PEW Trust and provides a comprehensive approach to implementing the practice.

Methodology

Root cause analysis can be conducted in a variety of ways but at a high level there are generally five key steps;

1) Define the issue: This step requires the gathering of data surrounding the issue to allow for a detailed and thorough investigation. This needs to include information about the issue such as what happened, when, where and how. Gathering records and any analytical evidence is important.

2) Investigate/identify the root cause: There are a number of approaches that can be used to assist the identification of the root cause of an issue but it is important to remember that it is the outcome that is the key here, not the methodology used. Choose an approach that works best for you and your team. The two most common techniques are the Five why’s and the Fishbone or Ishikawa model but others include Failure Mode and Effects Analysis (FMEA), Fault Tree Analysis (FTA) and Define, Measure, Analyse, Improve and Control Process (DMAIC). DMAIC is an integral part of Six Sigma but can also be used as a standalone tool for RCA.

3) Develop a preventive action plan: This consolidates the identification of the root cause with measures that can be implemented to prevent it recurring. This may include the need for new or modified procedures, equipment, training, etc.

4) Implement the action plan: The action plan may be simple but in many cases it requires investment in resource or capital to ensure it is effectively delivered and therefore measures should be in place to systematically deploy all actions needed.

5) Verify and monitor the action plan: Any new or changed process, procedure or equipment needs to be verified to ensure its effective ongoing operation and this may include new or modified process checks, internal audits or analytical testing.

In addition to their basic introductory video to RCA, the UK FSA has a wealth of useful guidance on RCA including an extensive online training package for food businesses and I would strongly advise those interested in developing their knowledge and skills in this area to use the resource. Other training is also available from organisations including BRCGS that provides greater detail for those who are likely to be applying RCA as part of their technical and food safety responsibilities.

Root Cause Analysis Insight

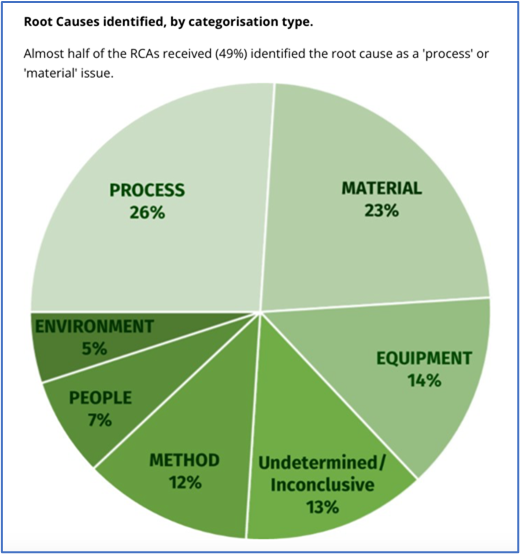

In the UK, the FSA requests that food businesses who have had a product recall complete a root cause analysis investigation and submit this to the agency (RCA form download). This allows the regulator to collate RCA data, analyse it and generate insight. This is published in its Incidents and Resilience Annual Report. The latest report (2022/23) noted that 2038 incidents had been reported during that period, a 13% decrease from the previous year. The top two hazard types for incidents reported were pathogenic microorganisms (28% of total) and allergens (15% of total). RCA was conducted on 325 incidents, with allergens, pathogenic microorganisms and foreign bodies driving the majority. The breakdown of the root causes demonstrated that process or material failures dominated the reasons with these categories, including aspects such as ingredient cross contamination, inadequate equipment cleaning and machinery damage.

|

Figure 1: Root Causes Identified, by categorisation type. Source: FSA

Role of Food Safety Management Software and Voluntary Third Party Assurance Schemes

A number of food safety management software systems exist these days that allow capture of corrective and preventive actions (CAPA) together with root causes such as the Safefood 360 platform. Being able to record and then report on these can assist food safety professionals to continuously improve their food safety plans and mitigate risks from prior learnings.

BRCGS has published a comprehensive guide on root cause analysis that is available free of charge via Participate or to purchase via the BRCGS Store.

Voluntary third-party certification programmes such as BRCGS Global Standard Food Safety Issue 9 require RCA to be completed to support the effective resolution of non-conformances arising during an audit, and also in the event of a site initiating a public recall of a product. The root cause is aligned to the corrective action and preventive maintenance (CAPA) to ensure satisfactory resolution of the issue or non-conformance and prevention of recurrence.

Summary

Root cause analysis is an important methodology to support continuous improvement in food safety management and, as a final thought, rather than using RCA in anger i.e. when you suffer a non-conformance or a product recall, why not take a leaf out of the health and safety guidebook and use RCA to assess near misses. How many times have you identified situations that could easily have become a non-conformance or led to a product recall, but that you rectified before such an eventuality? Embracing the proactive use of RCA to avoid non-conformances or serious incidents is surely one of the best uses of RCA that every food safety professional can adopt.

I hope this short overview of root cause analysis has whetted your appetite to delve deeper into the use of a tool and technique that is so important in the armoury of all food safety professionals.

|

Author

Alec Kyriakides BRCGS International Advisory Board Chair Independent Food Safety Consultant |